Integrity test found that 6% of the modules transported in non-recommended conditions and ordinary packaging showed microcracks

BYD Energy has become a pioneer in the sector by promoting integrity testing of the photovoltaic modules during transportation. To do this, the product was used in a road test of more than 2,300 kilometers, with travel on roads in poor condition.

The route included the harshest possible road conditions, passing over roads that were difficult to access, with poor or even non-existent paving. This was necessary in order to simulate, as faithfully as possible, the existing conditions for accessing the sites where the power generation plants are located, which are generally built in remote locations. In other words, these are complex locations that require prepared packaging to ensure product quality.

The road test, unprecedented in the segment at the time it was carried out, took place between the municipalities of Campinas (SP), where BYD Energy's headquarters are located, and Buritizeiro, situated in the northern region of Minas Gerais. "We wanted to simulate the worst possible transportation situation in order to find out about possible damage to the modules," said Rodrigo Garcia, Research and Development Manager at BYD Energy do Brasil. At the end of the journey, 6% of the modules transported in less than ideal conditions were found to have microcracks.

See also: A single door to knock on at the end of the day, if you need it

It is worth noting that modules and inverters are extremely sensitive electronic devices that need packaging to ensure they are protected during transportation or use. change. "In the test, we used packaging that is not in ideal condition and also our packaging, which has a structural function that enables stacking without excess strain on the module, avoiding micro-cracks. And the one with the 6% failure rate is normal packaging without reinforcements, used on a large scale in the market, which is not considered suitable for loading this type of product and which causes problems in the modules," says Garcia.

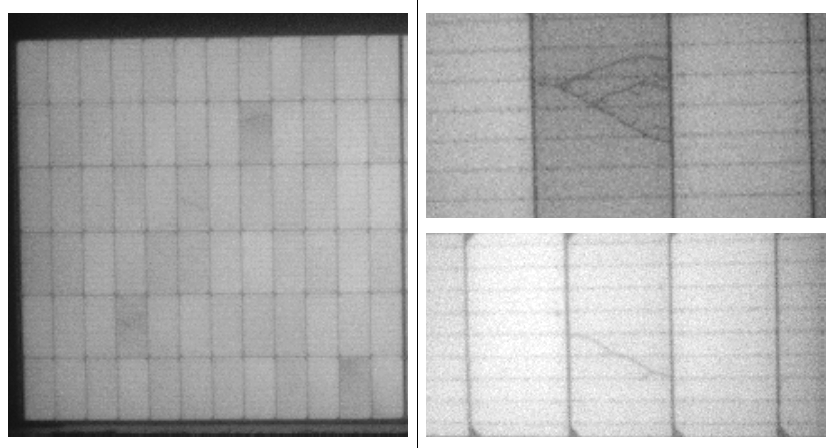

To give you an idea, these microcracks, invisible to the naked eye, can only be identified through an electroluminescence test, which is carried out in the company's laboratory in Campinas (SP), the only one of its kind in Latin America with the technology and know-how to carry out this assessment.

One of BYD Energy's great differentials is that each module produced is inspected before being delivered to the carrier, to ensure the perfect condition of the product before delivery to the customer. "The modules leave the factory with maximum integrity and zero risk, an added security and advantage for those who buy our products," adds Garcia.

Sturdy packaging for photovoltaic modules

To prevent, for example, this type of microcrack from appearing after long journeys and causing problems, BYD Energy has the most robust packaging on the market. solar energy of Brazil, which guarantees the total quality of the products that leave the factory for end customers all over the country. Those used by BYD Energy, for example, are twice as thick as those used in the market. This generates a resistance of 34 kgf.cm, compared to 15 kgf.cm used by other brands. It's a big differentiator.

To give you an idea of the level of quality, the packaging of the photovoltaic modules produced in China has the same quality standards as those manufactured in Brazil. Everything suits the interests of BYD Energy's Brazilian arm.

"There's no point in having a factory product in excellent condition and delivering it damaged to the customer. Its arrival in perfect condition depends very much on quality packaging. And what will the customer get out of it? A longer service life for the module. They won't have warranty problems and they'll achieve their goals in terms of energy generation. The customer has to believe that today every transport mechanism has been designed to avoid any kind of problem," Garcia concludes.